Handsaeme Machinery Timber frame houses

Machines for automated indoor construction of prefab building elements

Our machines streamline the off-site modular production of prefabricated walls, floors or roof panels. By making the panels indoor and away from the construction site, all elements of the process are optimized and made lean, which will result in higher yields. Also, this way a more ergonomic and safer workplace for the operators is created.

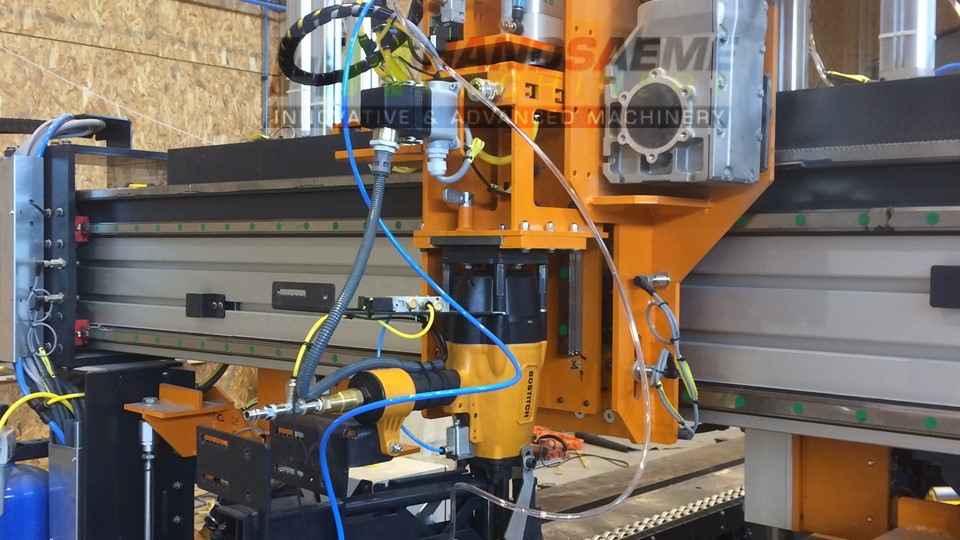

Next to the assembly of timber or metal frames, is it also possible to sheat the panels on the same machine with OSB, plasterboard, ... The complex attachment patterns to attach the panel elements together are simplified by automatic conversion to a specific fastening program from the 3D-drawings.

Fastening the elements can be executed in different ways; the most classic form is by nailing. Other methods, such as stapling or screwing are also possible, depening on the materials used.

The further handling and manipulation of the finished panels can be automated by turning systems, transporting systems, butterfly tables, etc.

➠ Discover the advantages & machines for optimizing off site production of (wooden) building elements➠ DOWNLOAD OUR (TIMBER) FRAME CONSTRCUTION BROCHURE |

Benefits Machines for prefab constructions

- Convert your 3D drawing to real building elements

- Simplification of complex attachment patterns

- More ergonomical working for the operators